If design and management are not connected

If the CAD system and the management tool are not integrated, entering the complete data of a project into the ERP becomes IMPOSSIBLE.

It’s an uncomfortable truth, but it is 100% real.

In engineering projects that involve design and manufacturing, the volume of information that should be managed in the ERP is enormous: hundreds or thousands of components with their references and all related information (including images), manufacturing processes, suppliers, complete bills of materials, and version management.

Entering and keeping all this data up to date is simply too complex, so most companies end up choosing not to do it.

Then the ERP is used… only halfway

The ERP is used to invoice, purchase some critical components, and handle administrative tasks — but not to manage inventory, manufacturing, assemblies, or to fully track project status in real time.

The consequences are clear:

- Purchases are not grouped or optimized

- There is no clear view of real inventory, nor of supplier inbound and outbound flows

- Manufacturing and assembly are managed outside the ERP

- Changes and corrections made during manufacturing are not reflected back in the design

In addition:

- Everything runs from one emergency to the next, because until something “burns,” it seems not to exist

- Information is scattered among people and departments, written down on sheets of paper, notebooks, and non-shared files

The result is always the same: errors, constant urgency, blind decisions… and a huge loss of time with a much higher economic cost than it appears.

The information already exists. It’s in the CAD

All — or almost all — the data needed to manage a project is already defined during the design process:

- Components with all their information

- Assemblies with complete bills of materials

- Supplier information and manufacturing processes defined as properties of the components themselves

There is no need to manually re-enter all this information into the ERP.

All that’s needed is a tool that collects this data completely and exports it to Odoo in a structured and consistent way.

Real integration between Onshape and Odoo

Our Onshape–Odoo Integration Add-in allows you to transfer all the information defined during the design process directly to the ERP, without having to manually re-enter it.

Bills of materials and components — including their images and properties — are exported in a structured and complete way, maintaining full consistency between design and management.

With just two clicks, all your design data is exported to Odoo, allowing you to manage inventory, manufacturing, and fully track your projects in real time.

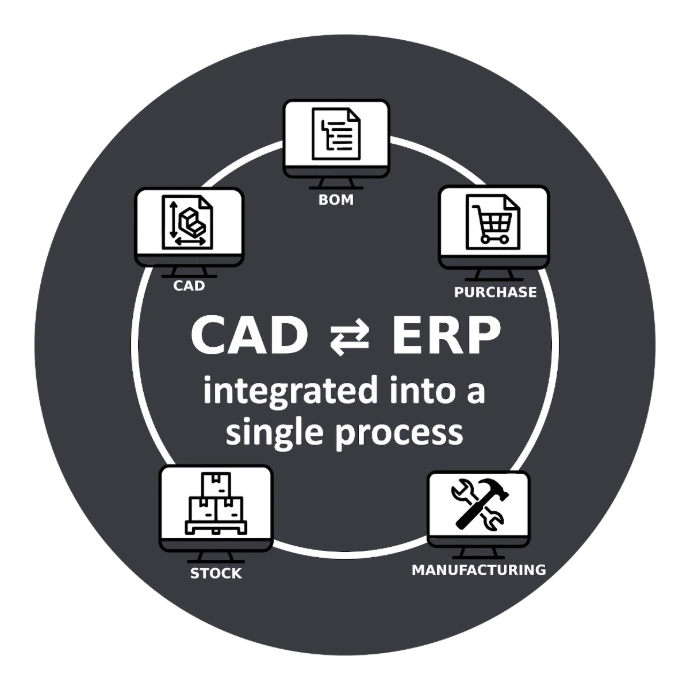

CAD and ERP stop being separate worlds and become fully integrated within the same process.

Is the Onshape–Odoo Integration Add-in useful for your company?

You can review the information below or contact C2i using the button in the top-right corner.

We’ll be happy to analyze your case and answer all your questions.

- Companies that work with project-based design

- Companies that design complex products or products with many components

- Companies with design and/or manufacturing processes that use Onshape

- Companies that design products and want to improve purchasing, manufacturing, and inventory control

- Massive manual data entry into the ERP (components and bills of materials)

- Lack of images for all products in the ERP

- Manual management of drawings, PDFs, and technical documentation

- Inability to properly manage inventory, manufacturing, and assemblies from Odoo

- Companies without in-house design

- Companies with very simple design processes

- Companies that carry out very simple projects, with no manufacturing or assembly

Let’s talk about your specific case

Schedule an online meeting with C2i. We’ll analyze how you design, manufacture, and manage your projects to determine whether this integration makes sense for your company — and how we can help you implement it.

Schedule an online meeting with C2i

30 minutes · Video call · No commitment